SCR-XA Scroll compressors

Basic description

- ANEST IWATA airends

- class 0 oil-free air

- V-belt transmission

- extremely low noise

- SCR9000 electronic controller with 7" touch display

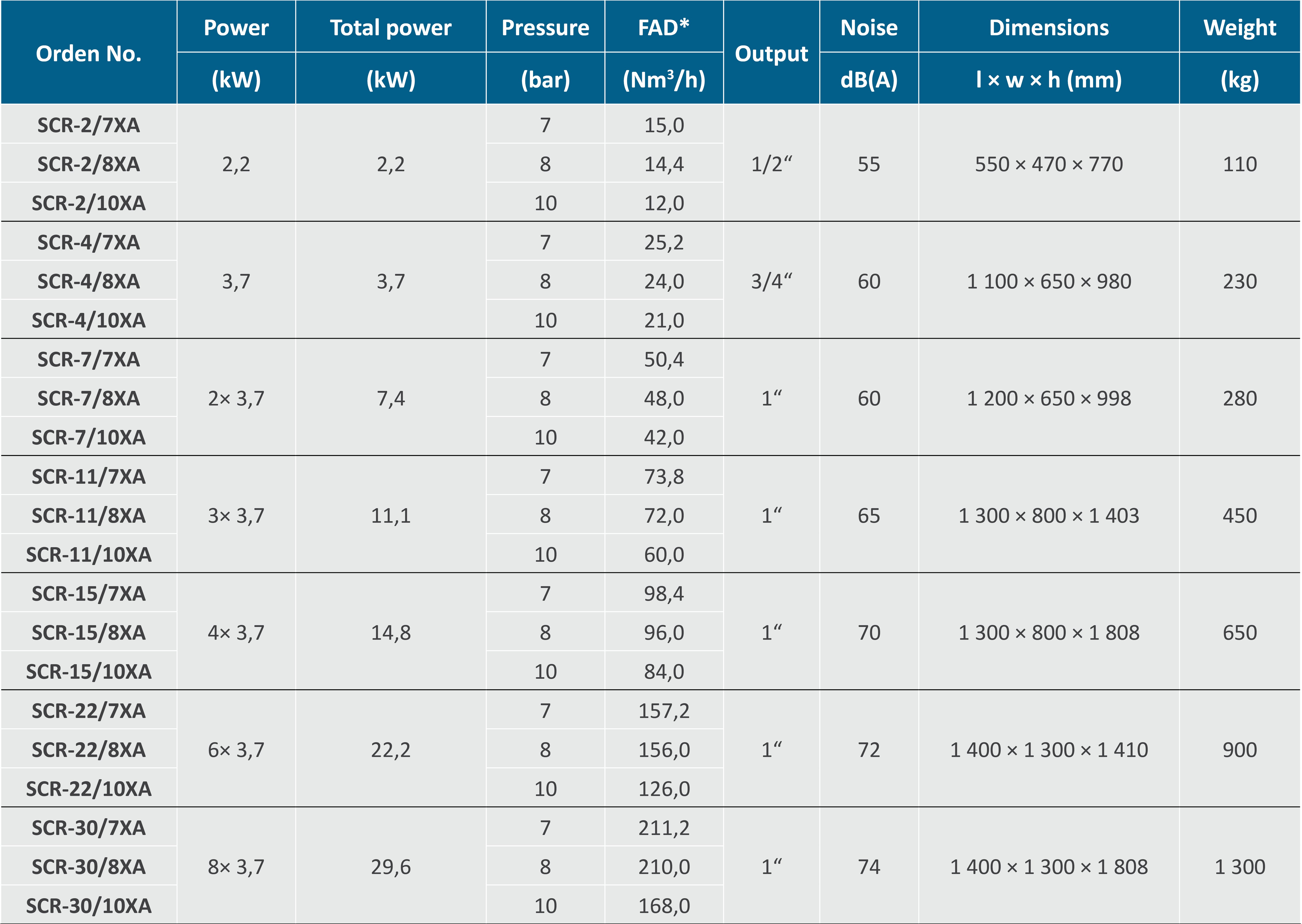

Power: 2,2-30 kW

Pressure: 7, 8, 10 bar

FAD: 12-211 Nm3/h

Product video

SCR-XA video

Get to know SCR-XA series through a video presentation.

Technical properties

Oil-free & silent

Scroll compressors do not need lubricating oil for their operation and provide completely oil-free air accounting requirements of class 0 for oil according to the ISO 8573-1 standard. The quality of the oil-free air supplied by the SCR-XA compressor is verified by certification by a notified body of TÜV Rheinland.

The very low noise level of SCR-XA series compressors enables their installation directly at the application site, and it is not necessary to build a compressor room with high costs and invest in a piping system.

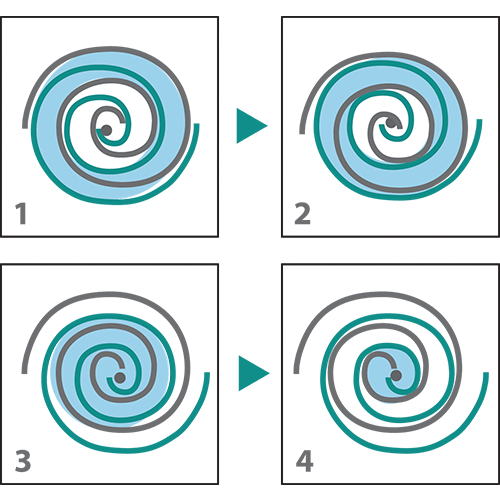

Design arrangement

Functional principles

The airend is made up of a fixed and movable spiral, which is connected to an electric motor and creates a rotating circular motion. Air from the atmosphere is drawn from the outer peripheral side of the block into the space between the two spirals and is gradually carried to the central part, where the compressed air outlet is located. As the air moves from the outer periphery to the center, the volume is gradually reduced and the pressure increased.

Top airends

Compressors of the SCR-XA series use high-quality spiral blocks of the renowned Japanese manufacturer ANEST IWATA for air production. Thanks to the fully robotic production of the blocks, each piece produced is practically identical.

In models with several airends, they are gradually switched on and off according to the current need for compressed air. The software in the control unit simultaneously ensures their regular replacement and optimizes their wear.

Modern electronic controller SCR9000

A modern system for controlling the operation of screw compressors with a comfortable 7" color touch screen and has the following functions and features:

- button control

- display of all necessary parameters about the operation of the machine

- indication of operational warnings and alarms

- alarm history for machine fault analysis

- user levels via passwords

- practical display of electricity consumption

- weekly schedule with 5 time slots for switching the compressor on and off

- automatic restart after power failure

Efficient cooling system

On the output the compressor, the temperature of the compressed air is reduced by means of aftercoolers installed at the output from each airend, in order to maximally reduce the water content created during compression.

To further reduce the operating temperature, the SCR-XA compressors are equipped with a radial fan on the airend and independent fans that remove heat from the compressor housing.

Metal hoses and pipes

All fluid connections in SCR-XA compressors are realized exclusively using metal hoses and metal pipes. With our machines, there is no risk of bursting or loss of air due to rubber hoses.

Comfortable service

After uncovering the panels with handles for easy handling, all structural parts are easily accessible and enable the convenient and fast work of service technicians.

Information materials

Presentation

CZ version PDF, 12,03 MBTechnical data

*FAD is measured according to ISO 1217, Annex C