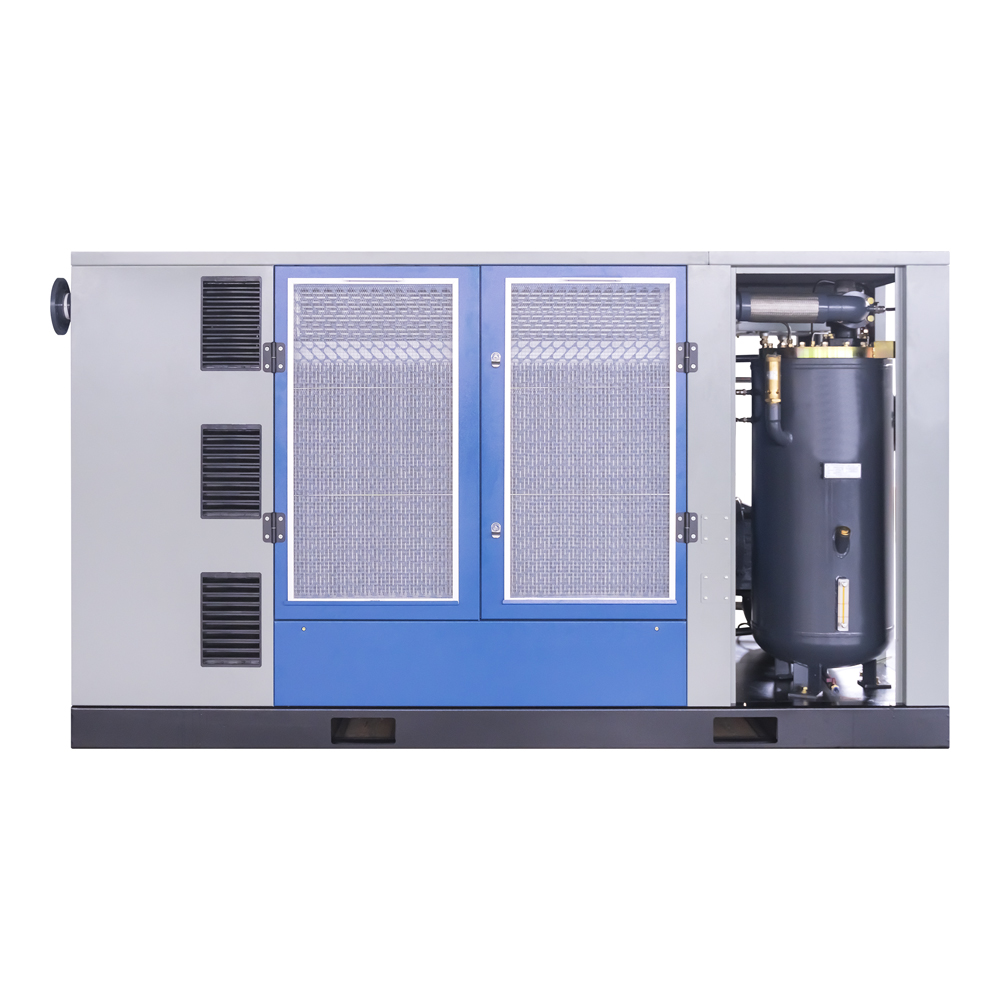

SCR-EPM2 Screw compressors

Basic description

- oil lubricated airend

- liquid-cooled PM-motor IE4

- speed control by frequency converter

- direct drive 1:1

- one-stage compressor

- SCR9000 electronic controller with 7" touch display

- ventilation with frequency converter

Pressure: 7, 8, 10 bar

FAD: 156-2010 Nm3/h

Product video

SCR-EPM2 video

Get to know SCR-EPM2 series through a video presentation.

Design arrangement

![]() airend

airend

![]() electric motor

electric motor

![]() air filter

air filter

![]() inlet valve

inlet valve

![]() oil receiver

oil receiver

![]() air and oil cooler

air and oil cooler

![]() oil filters

oil filters

![]() minimum pressure valve

minimum pressure valve

![]() electronic controller

electronic controller

![]() frequency converter

frequency converter

![]() electrical switchboard

electrical switchboard

![]() air outlet

air outlet

![]() motor cooling pump

motor cooling pump

![]() coolant chiller

coolant chiller

Technical properties

Extreme performance airends

Airends are the heart of screw compressors and airends on the SCR-EPM2 series are massive and provide such a huge amount of produced air that they can very often replace compressors with a power input of one to two orders of magnitude higher.

There is only a very limited number of compressors on the market that can compete with the FAD performance of the SCR-EPM2 series.

Lossles direct drive 1:1

Thanks to the direct connection of the airend to the electric motor, the SCR-PM series compressors operate without any energy loss in the transmission unit.

Compared to compressors with V-belts, coupling or gearbox, this eliminates any maintenance.

More about direct driveLiquid-cooled PM-motor IE4

The SCR-EPM2 series compressors bring to the market a unique technology of permanent magnet motors with independent liquid cooling, which due to their design have extreme efficiency, which far exceeds the efficiency requirements of IE4 according to IEC EN 60034 standard and exceed commonly used asynchronous motors by up to 5%.

More about PM-motor

SCR9000 electronic controller

Modern system for controlling the operation of screw compressors with a comfortable 7" color touch screen and has the following functions and features:

- button control

- display of all necessary parameters about the operation of the machine

- indication of operational warnings and alarms

- alarm history for machine fault analysis

- user levels via passwords

- practical display of electricity consumption

- weekly schedule with 5 time slots for switching the compressor on and off

- automatic restart after power failure

Frequency converters with vector control

The SCR-EPM2 compressors are equipped with state-of-theart INOVANCE frequency converters, which allow them to maintain the required output pressure and adapt the speed of the drive unit to the immediate needs of the compressed air supply.

The vector-controlled converters were specially developed for screw compressors and can provide very high torque at frequencies from 0.1 Hz.

Efficient oil separation

SCR-EPM2 series screw compressors are equipped with a highly efficient oil separation system that ensures perfect compressed air output quality with a peak oil content of < 3 ppm.

The oil is separated by a three-stage separation system using centrifugal force, gravity effect in a vertically oriented oil receiver and a high-quality separation filter.

Efficient filtration system

Oil filtration

Ensuring high oil quality without impurities is a key issue for perfect compressor performance. SCR-EPM2 compressors use high-quality oil filters, which are equipped with a pressure drop switch for models from 75 kW.

Air filter

SCR-EPM2 compressors are equipped with a two-stage air filter for increased protection of the airend against possible entering of solid dirt that could damage the rotors.

Information materials

Prezentace

CZ version, PDF 5,86 MBTechnical data

FAD performance is measured according to ISO 1217 and is listed for the maximum pressure of the model; additional FAD performance values at different frequencies and pressures can be found in the technical data sheets on request.

The noise level is indicated at a distance of 1 m from the machine.